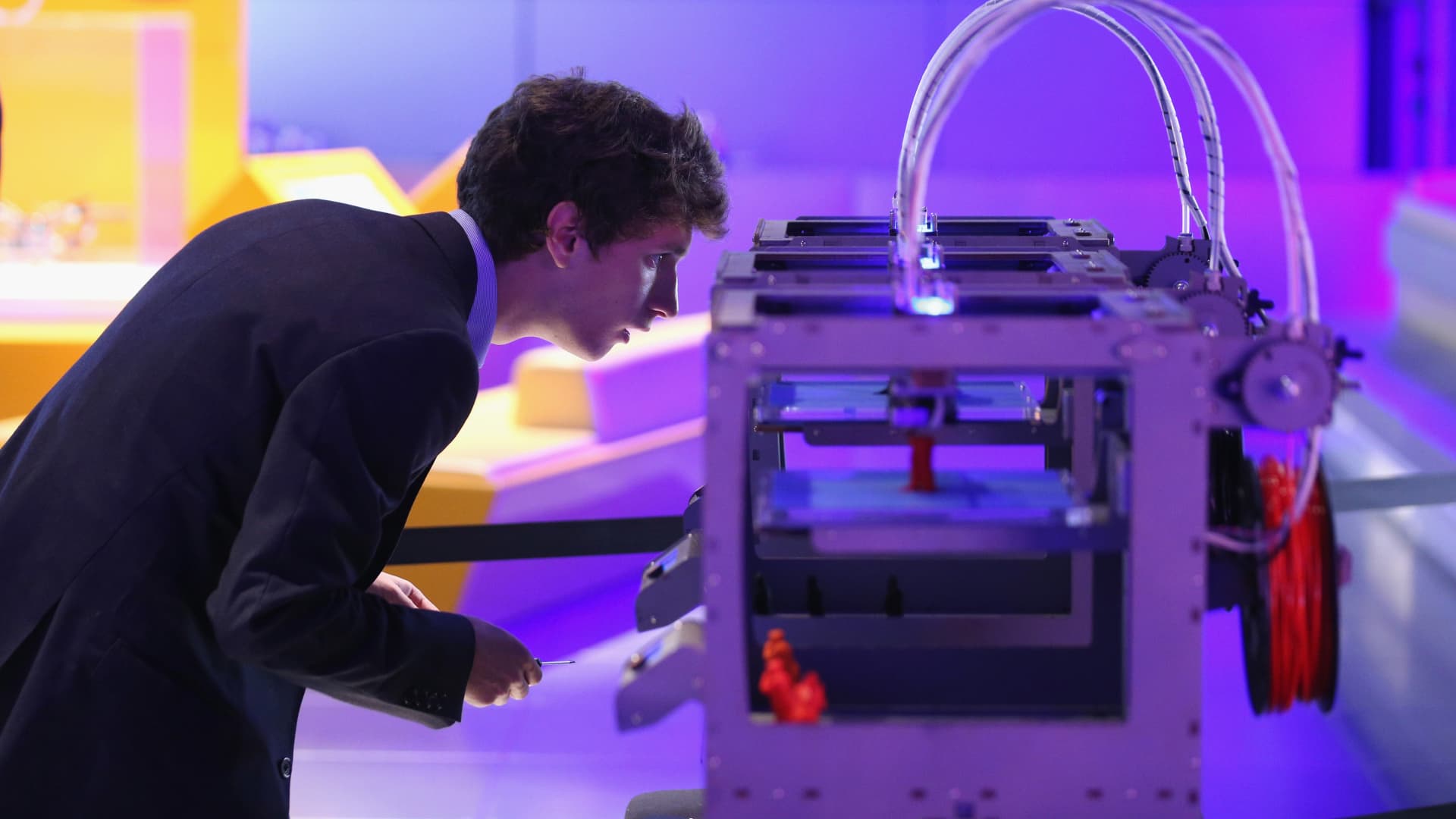

The new era of 3D printing “microfactors” will help the residual plastics to transform “highly competitive” products into “high competitive” products, Veena Sahajwalla, Veena Sahajwalla, Professor and UNSW Regulations and Technology (SMART).

Sadney Innovation Summit in Symney’s Sydney Innovation Summit in Mandy’s Sydney Innovation Summit in Mandy, Sadney to Sadney, and manufacturers are focused on profitability of stability.

“I’ll make it green because I make it hidden. Actually, this should be the last thing. First thing to appear, should he work properly? ” He said.

This thinking smartly pushed up to build 100% garbage plastic plastic threads from all types of old printers.

They are built in highly automated “microfactors” to produce hyper-localized, individual products.

“If this (waste disposal plastic) can now be supplied to 3D printers, can you print all the range of products?” He said.

One such product is “clamps” – or blocks – used in construction and construction projects.

“Imagine all building and construction projects, imagine that if you need to wait for these particles and components,” he said.

High plants during construction projects Companies often buy them a second time.

Smart’s is made with a 3D-printed alternative, old, plastic waste, low costs, because the costs are lower than the bottom, because the Sacagwolla.

“You can talk to your local microfactors and can say that I can do this at a relative price and correct performances?”

“There were microffor technologies. On the other hand and on the other hand, high productivity, high-tech and competitive one closure of gaps.

Hydrogen revolutions?

Pure hydrogen-based energy-based autonomous trucks and buses, thanks to this technology, thanks to this technology.

Scott Brown, Pure Hydrogen Managing Director, with its firm, has a litter to produce garbage to its firm “no diesel without diesel”, which is low in the morning during the morning.

He predicts a decrease in fuel cells for next 10 to 15 years.

Car manufacturers HondaWhere Toyota and Hyundai have accepted a large amount of fuel-cellular engineering.

Fuel cells mean the use of hydrogen or other fuels to generate clean electricity.

“Not many participants. It looks like a computer and you put it on it and you are in our case – a truck or bus, “said brown.

As there is production due to reproduction, the price of fuel and lubricants will receive “50% over the past three years”, – he said.

In the coming decade, the price of pure energy is predicted that the price of pure energy will be “sharply and falls sharply” because Chinese companies provide hydrogen capacity.

Amid Figures produced by South Korea SME Research Group In November, the sale of hydrogen commit commercial vehicles in China remained out of buying around the world.